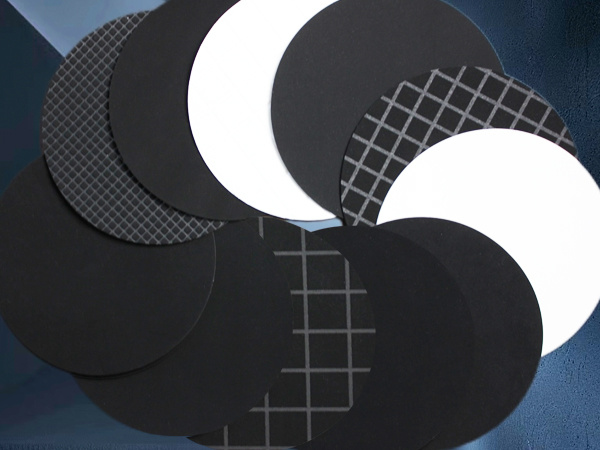

Polyurethane grinding and polishing material

Polyurethane (PU) grinding and polishing materials are high-performance industrial consumables designed using the properties of polyurethane materials. They are widely used in fields such as semiconductors, optical glass, and metal processing. Their core advantage lies in achieving efficient and uniform grinding and polishing effects through the synergistic action of materials and structures.

● Material Properties and Design

Polyurethane polishing consumables: possess high wear resistance, chemical corrosion resistance (oil and acid-base resistance), and controllable hardness (Shore hardness 45A~90A), suitable for different polishing needs.

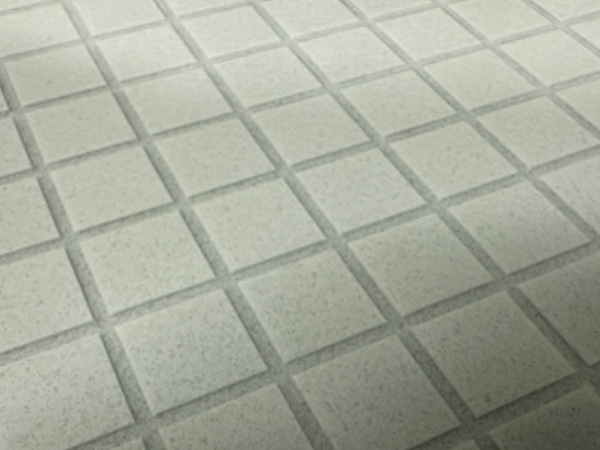

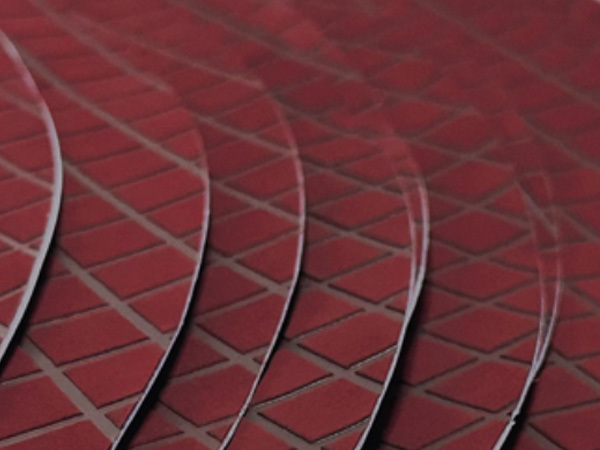

● Structural Design

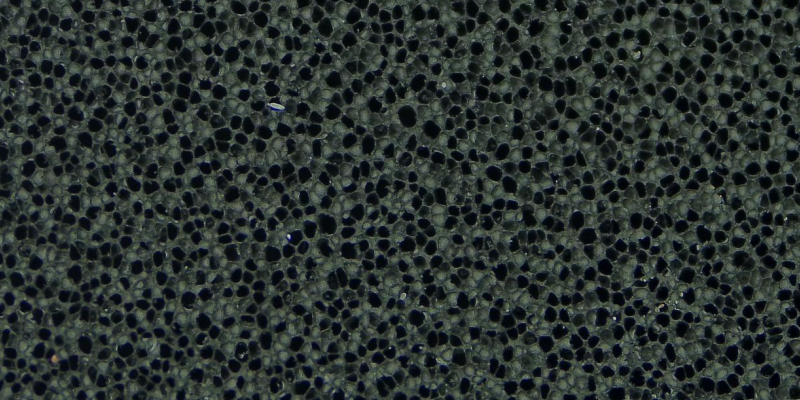

Porous structure: open-cell or closed-cell foam design (pore size 10 to 100 μm), used for storing and delivering polishing fluid, ensuring the uniform distribution of abrasives during the polishing process.

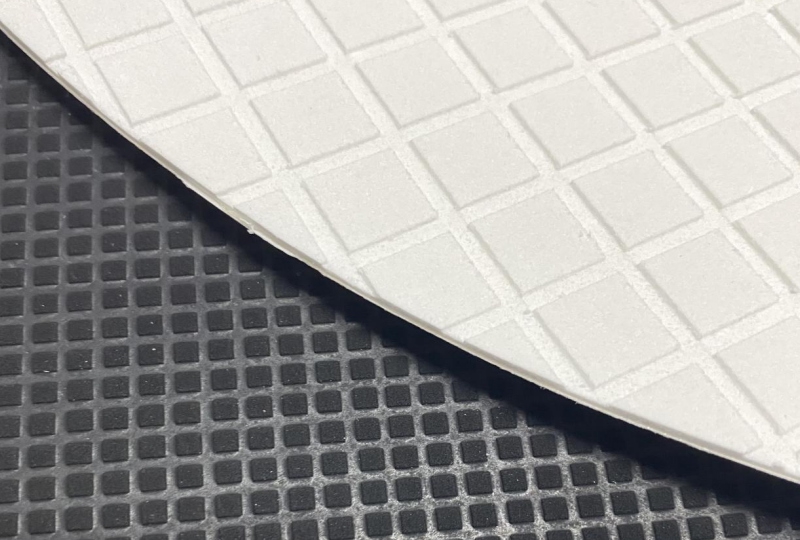

Surface texture: grooves, grids, or bump patterns, optimizing the flow path of polishing liquid, reducing scratches, and improving flatness.

● Working Principle

Chemical-Mechanical Polishing (CMP)

Chemical action: The active ingredients in the polishing liquid (such as pH regulators) soften the surface of the workpiece, accelerating polishing efficiency.

Physical grinding: The elastic surface of the polyurethane pad contacts the workpiece through micro-protrusions, combined with abrasive particles (such as silica, alumina) to achieve material removal.