Infrared military industry

In the field of infrared military industry, chemical mechanical polishing (CMP) technology is widely used in the manufacturing process of various key materials and devices due to its high precision and high efficiency in surface treatment. Wanhua New Materials has the following polishing consumables in this field:

CMP technology is widely used in the infrared military industry, covering various aspects such as infrared optical devices, infrared sensors, infrared films, infrared lasers, and infrared imaging systems. Its high precision and high efficiency in surface processing make CMP an indispensable key technology in the manufacturing of infrared military products.

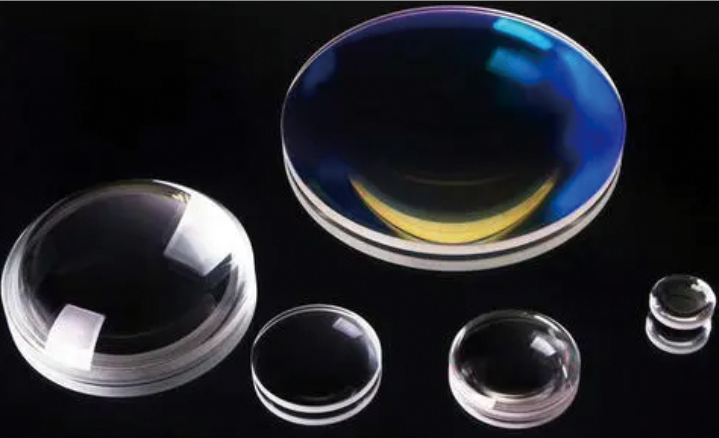

1. Infrared Optical Devices

Infrared lenses and windows: Infrared optical devices (such as lenses and windows) require extremely high surface flatness and smoothness to ensure accurate transmission and reflection of infrared light. CMP technology can process the surfaces of these optical materials to achieve extremely high flatness, eliminating small bumps and defects, thereby improving optical performance.

Infrared detectors: The surface flatness of infrared detectors directly affects their detection accuracy and sensitivity. CMP technology can be used for polishing the surfaces of infrared detectors, ensuring their surface flatness and optical performance.

2. Infrared Sensors

Infrared sensor substrates: The substrates of infrared sensors require highly flat surfaces to ensure accurate signal reception and processing. CMP technology can be used for polishing sensor substrates, improving their performance and reliability.

3. Infrared Films

Surface treatment of infrared films: Infrared films are used to enhance or control the transmission and reflection characteristics of infrared light. CMP technology can be used to process the surfaces of infrared films, ensuring their flatness and uniformity.

4. Infrared Lasers

Polishing of infrared laser substrates: Infrared lasers have extremely high quality requirements for substrate surfaces, typically requiring a surface roughness of less than 0.1μm and a thickness variation of less than 10μm. The CMP (Chemical Mechanical Polishing) process is the preferred technology that can meet these high precision requirements.

5. Infrared Imaging Systems

Components of infrared imaging systems: The components of infrared imaging systems (such as mirrors and prisms) require extremely high surface flatness and smoothness to ensure imaging quality. CMP technology can be used for polishing these components, improving the performance of the imaging system.

|

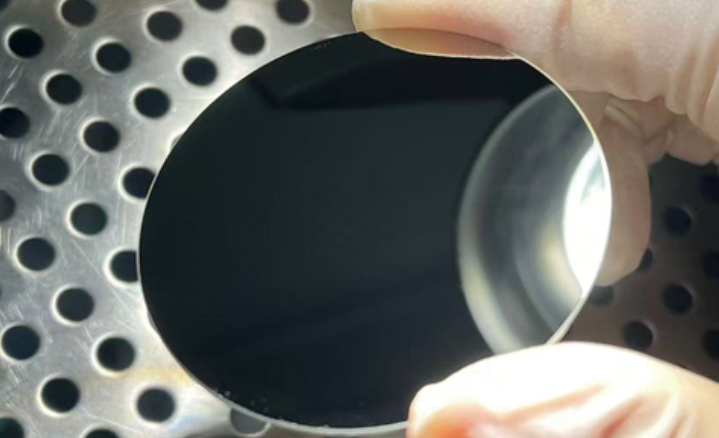

Silicon wafers |

Germanium wafers |

Indium antimonide |

Calcium fluoride |